My Journey from Chaos to Clarity: Why Taking a Lean Management Course Was My Best Decision

Remember those days when your to-do list felt like a never-ending scroll, your projects seemed to hit invisible walls, and your work environment, well, it just felt… heavy? I certainly do. Not so long ago, my professional life felt like I was constantly paddling upstream, putting in a ton of effort but often feeling like I wasn’t getting anywhere fast. There was a constant hum of inefficiency, a subtle but persistent drain on energy and resources, both mine and my team’s.

Then, I heard whispers about something called "Lean." At first, it sounded a bit like a new diet trend for businesses – "get lean," "cut the fat." I was intrigued, but also a little skeptical. Could a management philosophy really change things that much? Could a Lean Management Course truly be the answer to my unspoken frustrations? Spoiler alert: It was, and then some. Let me tell you about my journey.

The Spark: What Even Is Lean Management?

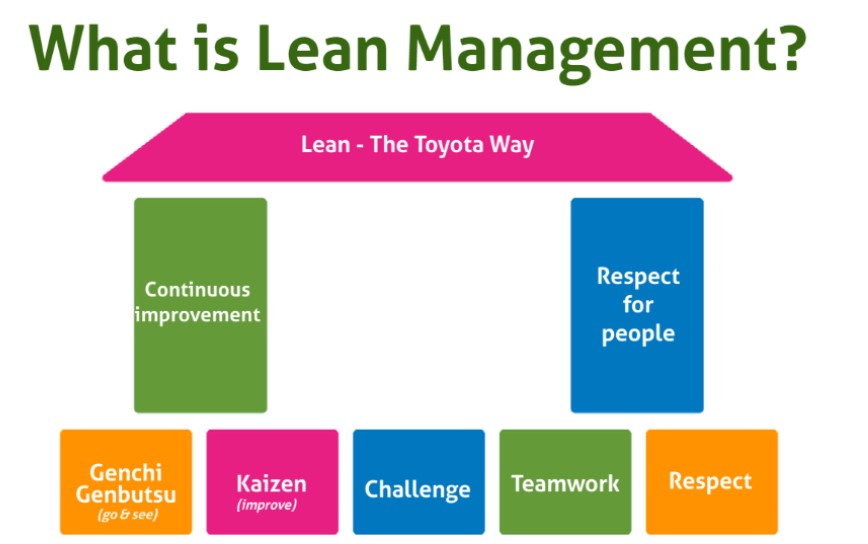

Before I even considered enrolling in a Lean Management Course, I had to get my head around what Lean actually meant. My initial understanding was vague: "making things more efficient." But the more I looked into it, the more I realized it was much deeper than just efficiency. It’s a way of thinking, a philosophy that originated from Toyota, focusing on maximizing customer value while minimizing waste.

Think about that for a second: maximizing value, minimizing waste. It sounded like common sense, right? But how do you actually do that in the messy reality of daily operations? My work, like many people’s, involved layers of processes, hand-offs, approvals, and sometimes, just plain old waiting. I suspected there was a lot of waste, but I couldn’t quite put my finger on where or how to tackle it. This growing curiosity was the first step towards my decision to actively seek out a Lean Management Course.

Taking the Leap: Choosing My Lean Management Course

The internet is a vast ocean, and finding the right Lean Management Course felt a bit daunting. There were certifications, online modules, in-person workshops, and various levels (Yellow Belt, Green Belt, Black Belt – it sounded like martial arts!). As a beginner, I knew I needed something that started with the fundamentals, explained concepts clearly, and offered practical tools I could actually use. I wasn’t looking to become a Lean Sensei overnight, just to understand the core principles and how to apply them.

I opted for an online course that offered a good blend of theory and practical exercises, with a focus on real-world examples. It was a commitment of time and effort, but I told myself it was an investment in my sanity, and potentially, my career.

Stepping Into the Classroom (Virtually): The "Aha!" Moments Began

From the very first module, my eyes started to open. The instructor wasn’t some stuffy academic; they were someone who had lived and breathed Lean in various industries. They spoke in a way that made complex ideas feel simple and relatable.

One of the first big revelations was understanding the Eight Wastes of Lean (Muda). This wasn’t just about throwing out old papers; it was about recognizing:

- Defects: Errors that require rework. (Think sending out an email with a typo and having to correct it).

- Overproduction: Making more than is needed. (Creating a report nobody reads).

- Waiting: Time spent doing nothing. (Waiting for approval, waiting for a file).

- Non-Utilized Talent: Not using people’s skills effectively. (Having an expert do entry-level tasks).

- Transportation: Moving things unnecessarily. (Shifting files between too many folders).

- Inventory: Excess materials or information. (Too many drafts, too many old files).

- Motion: Unnecessary movement by people. (Walking across the office for a pen).

- Over-processing: Doing more work than required. (Adding extra steps to a form).

As the instructor walked through each waste, I found myself nodding vigorously. "Oh, that’s what that’s called!" I thought. My own work, and frankly, my entire company, was riddled with these wastes. It was like suddenly being given special glasses that let me see the invisible energy drains everywhere. This foundational understanding from my Lean Management Course was already paying dividends.

Unveiling the Lean Toolkit: Practical Solutions for Real Problems

The course didn’t just tell me what was wrong; it taught me how to fix it. This was the truly exciting part. We delved into practical tools and methodologies that felt like superpowers for efficiency.

- Value Stream Mapping: This was like drawing a detailed map of a process, from start to finish. It helped me visualize where value was added and, more importantly, where it wasn’t. It showed me the actual flow, not just the idealized one. I used it to map out our project onboarding process, and the sheer number of waiting steps was astonishing!

- 5S (Sort, Set in Order, Shine, Standardize, Sustain): This framework for workplace organization might sound simple, but its impact is profound. My desk, which used to be a war zone of scattered notes and half-finished coffees, became a model of order. More importantly, I applied the principles to my digital workspace – my inbox, my computer folders. The reduction in wasted time searching for things was immediate.

- Kaizen (Continuous Improvement): This beautiful concept taught me that improvement isn’t a one-time big bang; it’s a series of small, continuous changes. We learned how to identify tiny problems and fix them right away, rather than letting them fester. "Don’t wait for perfection," the instructor said, "just make it a little bit better today." This shifted my entire mindset about problem-solving.

- Root Cause Analysis (e.g., The 5 Whys): Instead of just patching symptoms, this taught me how to dig deeper. When something went wrong, instead of just fixing it, I learned to ask "Why?" five times (or however many it takes) to get to the fundamental cause. This stopped recurring problems in their tracks.

Every module of the Lean Management Course felt like unlocking a new level in a game, equipping me with tools to tackle challenges I previously thought were just "part of the job."

Bringing Lean Home: Applying What I Learned

The real test, of course, was applying these concepts in my actual work. It wasn’t always easy. Old habits die hard, and sometimes, change can be met with resistance. But armed with the knowledge from my Lean Management Course, I started small.

My first target? Our weekly team meeting. It used to drag on for an hour, often without clear outcomes. Applying Lean principles, I:

- Defined the value: What was the actual purpose of this meeting? (Decision-making, problem-solving, not just information sharing).

- Eliminated waste: We cut down on irrelevant updates (over-processing, waiting).

- Standardized the agenda: Everyone knew what to expect (5S, standard work).

- Implemented a timekeeper: To keep us on track (motion, waiting).

The result? Our meetings became shorter, more focused, and actually productive. People left feeling energized, not drained. This small win gave me the confidence to tackle bigger projects.

I used Value Stream Mapping to analyze our client onboarding process, identifying bottlenecks that caused delays and frustration. By streamlining hand-offs and clarifying responsibilities, we cut down the onboarding time significantly, leading to happier clients and less stress for my team.

It wasn’t just about work, either. I found myself applying Lean thinking to my personal life – organizing my home, planning my errands, even decluttering my digital life. The principles are universal.

The Ripple Effect: My Life After the Lean Management Course

Today, I look back at my "before" self and barely recognize the overwhelmed person I once was. Taking that Lean Management Course wasn’t just about learning a new set of tools; it was about adopting a new way of seeing the world. It’s about cultivating a mindset of continuous improvement, always looking for ways to add value and eliminate waste, whether in a large organization or in my daily routine.

The benefits have been tangible:

- Increased Efficiency: My team and I get more done with less effort.

- Reduced Stress: Less firefighting, more proactive problem-solving.

- Improved Quality: Fewer errors, better outcomes.

- Enhanced Team Morale: Everyone feels more engaged and empowered to make improvements.

- Career Growth: This new skillset made me a more valuable asset, opening doors to new opportunities.

If you’re feeling that familiar hum of inefficiency, that subtle drain on your energy, or just want to gain a powerful set of skills that are applicable across any industry, I wholeheartedly recommend exploring a Lean Management Course. It’s not magic; it’s just smart thinking, taught in a structured way that empowers you to make real, lasting change.

It was my best decision, and I believe it could be yours too. Start your own journey from chaos to clarity – you might be surprised at how much brighter things look on the other side.