Ever wondered how your favorite coffee shop always seems to have your preferred beans in stock, even during a rush? Or how that massive online retailer gets your package to your doorstep so quickly, seemingly from thin air? For the longest time, I used to think it was just… magic. Or maybe incredibly organized people running around with clipboards. Then, I stumbled upon something called an "Operations Management Course," and let me tell you, it was an eye-opener.

If you’re a beginner, maybe someone just starting to dip their toes into the vast ocean of business studies, or even an entrepreneur trying to make sense of your own processes, this story is for you. I’m going to walk you through my experience with an Operations Management (OM) course, not as a textbook, but as a real-life discovery.

From "What’s That?" to "Aha!" – My Introduction to Operations Management

When I first saw "Operations Management" on my course list, I’ll admit, the name sounded a bit dry. "Operations? Like, surgery? Or military ops?" I chuckled to myself. Little did I know, it would completely change my perspective on how businesses, big and small, actually function.

My instructor, a seasoned professional with a knack for making complex ideas feel like everyday conversations, kicked things off by asking a simple question: "What does it take to get a product or service from an idea into the hands of a customer?" That question, innocent as it sounded, was the starting point of understanding what Operations Management truly is.

Imagine OM as the conductor of an orchestra. The conductor doesn’t play every instrument, but they ensure every musician plays their part at the right time, in harmony, to create beautiful music. Similarly, an operations manager doesn’t do every single task in a company, but they design, run, and improve the processes that make products or deliver services. It’s about making things smoother, faster, better, and with less waste. From brewing your morning coffee to building a skyscraper, OM is the silent force making it all happen.

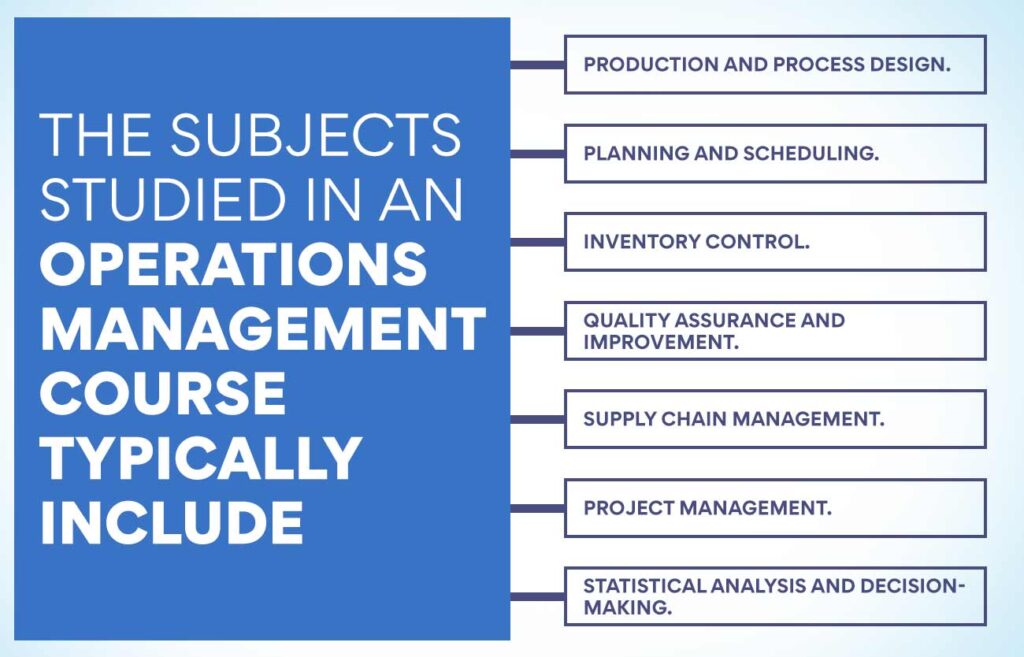

Stepping Into the Workshop: What We Really Covered

The course wasn’t just lectures; it felt like we were peeking behind the curtain of countless businesses, analyzing their inner workings. Here’s a glimpse into the key areas that truly resonated with me:

1. Understanding Process Flow and Efficiency

Our first deep dive was into "process mapping." This sounds technical, but it’s really just drawing out every step involved in making something or delivering a service. Think of it like drawing a detailed map of how you make breakfast, from getting ingredients out of the fridge to taking the first bite.

We learned to identify bottlenecks (those frustrating points where things slow down), eliminate unnecessary steps, and generally make the whole process more streamlined. It was like solving a puzzle, always looking for a more elegant solution. Suddenly, I started seeing processes everywhere – how I packed my bag for class, how my friends organized a group project, even how traffic flowed (or didn’t!) in the city.

2. The Grand Journey: Supply Chain and Logistics

Before this course, "supply chain" was just a vague term I heard on the news. Now, it became a living, breathing network. We explored how raw materials travel from their source, get transformed into products, and then reach the customer.

I started thinking about the journey of my smartphone: where did the components come from? How did they get to the factory? How was it assembled? How did it end up in my hand? It’s an intricate dance involving suppliers, manufacturers, warehouses, transportation companies, and retailers. We talked about getting the right stuff, to the right place, at the right time, and at the right cost. It was fascinating to see how a hiccup at one point could ripple through the entire chain.

3. Getting It Right: Quality Management

This wasn’t just about "good" or "bad" products. Quality management, as we learned, is a systematic approach to ensuring consistency and meeting customer expectations. We discussed methods for identifying defects, preventing them from happening in the first place, and continuously improving what’s being offered.

It struck me how much effort goes into making sure that every cup of coffee from a chain tastes the same, or that every car model meets specific safety standards. It’s about building quality into every step, rather than just inspecting for errors at the very end.

4. The Goldilocks Principle: Inventory Management

"Too much or too little?" That was the core question here. Having too much inventory means money tied up in goods sitting around, potentially going bad or becoming outdated. Having too little means you might run out when customers want something, leading to lost sales and unhappy people.

We explored strategies for finding that "just right" balance – predicting demand, figuring out optimal order quantities, and managing storage. It was like a constant balancing act, trying to keep things flowing without overstocking or understocking.

5. Project Management – The Big Picture

While often a separate field, Operations Management has strong ties to Project Management. We touched on how projects, which are temporary endeavors to create a unique product or service, often feed into or come out of ongoing operations. Understanding how to plan, execute, and close projects effectively is crucial for improving operations or launching new initiatives.

Who Should Consider an Operations Management Course?

Honestly, anyone curious about how the world works, how products get made, or how services are delivered would find value here. But specifically, if you’re:

- An aspiring manager: Understanding operations is fundamental to leading any team or department.

- An entrepreneur: If you’re building a business, you are an operations manager, whether you know it or not! This course gives you the tools to do it well.

- A business student: It provides a crucial foundation, connecting the dots between finance, marketing, and human resources.

- A problem-solver at heart: If you love puzzles, optimizing things, and finding more efficient ways to do tasks, this field is for you.

My Unseen Benefits and Takeaways

Beyond the grades and the textbook knowledge, this Operations Management course gave me something much more valuable.

Firstly, it equipped me with a whole new lens through which to view the world. I started noticing the queue management at the supermarket, the layout of a factory floor in a documentary, or the steps involved in ordering food online. Everything became a process waiting to be analyzed and potentially improved.

Secondly, it honed my problem-solving skills. Instead of just seeing a problem, I started breaking it down into its components, tracing it back to its root cause within a process, and brainstorming practical solutions.

Lastly, it showed me the power of organization and systematic thinking. It’s not just about working hard; it’s about working smart. It’s about designing systems that allow people to do their best work, consistently and effectively.

My Advice to You

If "Operations Management Course" ever pops up on your radar, don’t let the name intimidate you. Embrace it! Go in with an open mind, ask questions, and try to connect everything you learn to real-world examples you encounter every day. You’ll be surprised at how much sense it all starts to make.

It’s more than just a business course; it’s a foundational pillar that helps you understand the mechanics behind almost everything around us. And who knows, it might just spark a passion for making things work better, faster, and smarter, just like it did for me.